- Home

- About Us

- Robots

- Manipulator (Robotic Arms)

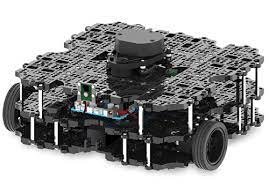

- Robotnik

- Mobile Manipulator Robots

- Research Platforms

- Occam Vision

- Parallel Platform

- Accessories

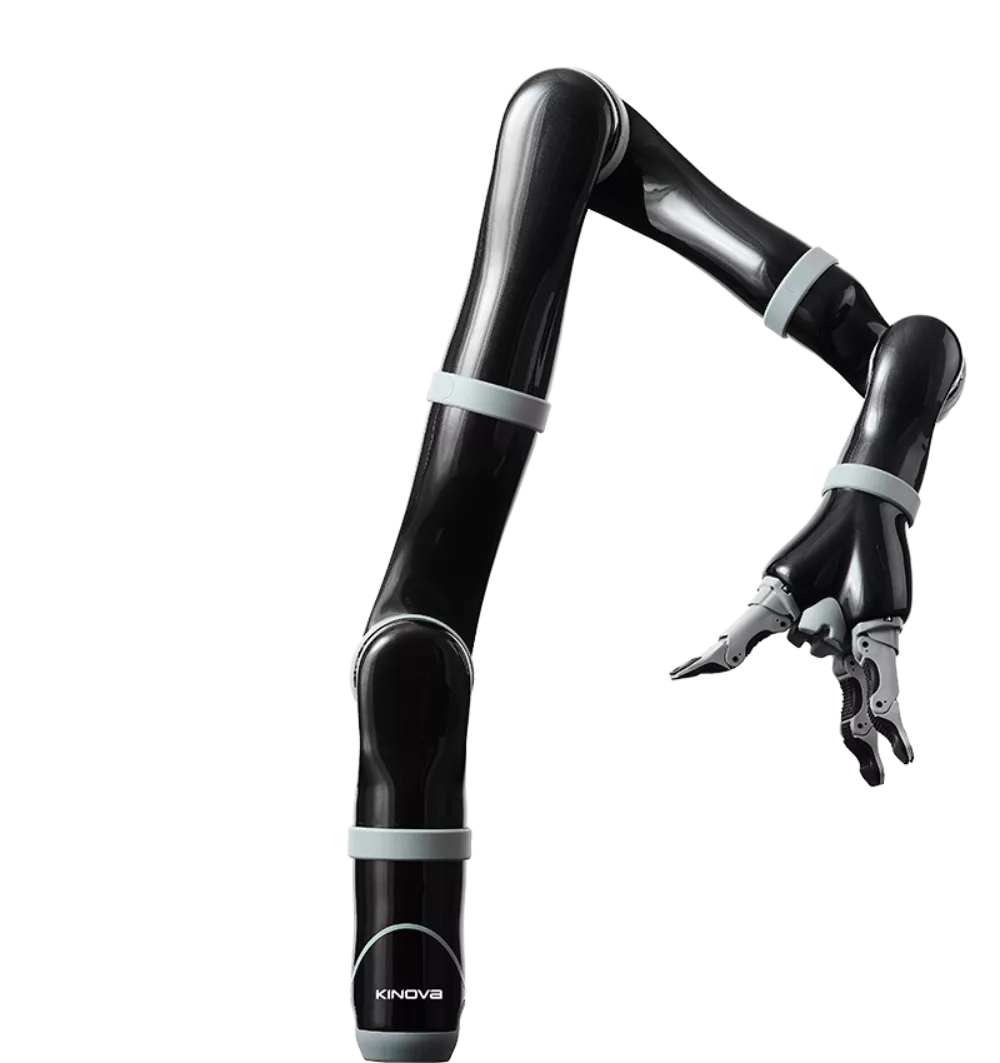

Gen2 robots

JACO² 4 DOF

Gen2 robots

JACO² 6 DOF

Gen2 robots

JACO² 7 DOF

Gen3 Lite Robots

GEN3 LIGHT ROBOT

Accessories

Sensors

Accessories

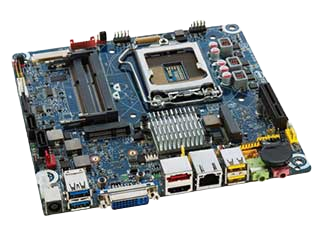

Computers & Networking

Accessories

Controllers

Accessories

All Accessories

- Applications

- Seminars

Robotic Training & Workshop at PSG College of Technology, Coimbatore

December 1, 2018National Conference On Scientific Advances In Engineering, Chennai

November 1, 2018Inauguration Ceremony of MIT Robotics Association, MIT, Chennai

September 1, 2018AGV Workshop @ IIT Kharagpur – October 2017

October 1, 2017 - BOOK YOUR SLOT AT AIR 2025